Rod

With over 2,500 products, Lewis Brass & Copper makes it easy to find your particular product. Below is a list of our stocked products we supply.

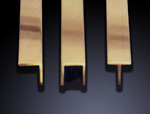

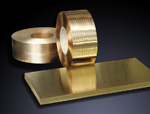

Our product range includes brass, bronze, and copper rods in multiple shapes and sizes to support everything from architectural projects to precision manufacturing. We stock various different shapes, including round, square, rectangular, or half oval rods, with our inventory tailored to meet both standard and custom requirements.

By maintaining a wide selection, we help customers in industries like construction, electrical engineering, and decorative design find exactly what they need without delay. Our reputation is built on speed, reliability, expertise and providing high-quality metals, in stock to meet your project demands.

Our immense in-stock inventory helps us fulfil your orders quickly.

Browse Our Rod Products

Browse related products

Not seeing exactly what you are looking for? Drop us a note or call, and we will custom create your order.

Why Choose Lewis Brass?

Over Six Decades of Expertise

With over six decades of expertise supplying brass and copper products, we’ve built lasting relationships with industries nationwide. Our history ensures customers can trust our knowledge, consistency, and reliability.

Extensive Inventory

We carry one of the largest selections of non-ferrous metals in the United States, including over 2,500 stocked products. This means you can source multiple materials from a single supplier without delays.

Fast Turnaround

Our immense in-stock inventory allows us to fulfill orders quickly, keeping your projects on schedule. We also offer precision cutting services to deliver materials exactly to your specifications.

Expert Guidance

Our knowledgeable team helps customers select the right product for their application, whether it’s for electrical conductivity, decorative use, or heavy-duty industrial requirements.

Competitive Pricing

By maintaining large inventories and strong supplier relationships, we provide premium metals at fair, market-driven prices that deliver long-term value.

Trusted Reputation

Lewis Brass & Copper has been serving industries for decades, building a reputation for reliability, quality, and customer-first service on projects of every size.

FAQs

What are the key characteristics of a 110 copper round rod for various uses?

The 110 copper round rod has high electrical and thermal conductivity for efficient heat dissipation and reliable connections. This material is very malleable so it’s easy to shape and fabricate and manufacturers can create complex parts.

It’s also resistant to corrosion so it’s a good choice for applications in wet or chemical environments. In addition, it has excellent ductility, making it ideal for both hot and cold working processes.

Its versatility means it can be found in electrical components, plumbing systems, and even artistic applications where precision and strength are required.

How does the strength of a 110 copper round rod compare to other copper alloys?

The 110 copper round rod has a good balance of electrical conductivity and mechanical strength. It may have slightly lower tensile strength than other copper alloys but its conductivity is often more important in many applications.

This makes the 110 copper round rod the preferred choice among designers and engineers who need materials that prioritize electrical performance without sacrificing durability.

Compared to alloys like brass or bronze, 110 copper offers unmatched conductivity, though it is not as hard as some alternatives. Engineers often weigh this trade-off depending on whether the application demands higher electrical performance or superior wear resistance.

What forms can 110 copper round rods be used in manufacturing?

110 copper round rods are versatile materials that can be machined, formed or welded easily for various manufacturing processes. Typical applications are fabricating connectors, terminals and screws.

Each of these parts benefits from the combination of mechanical strength and conductivity so it’s optimum performance in demanding applications such as electrical systems or precision instruments. This is a testament to our expertise in creating quality copper products for various industry needs.

What industries commonly use 110 copper round rods?

110 copper round rods are widely used in industries such as electrical engineering, telecommunications, construction, and plumbing. Their superior conductivity makes them essential for connectors, busrods, and grounding systems.

In construction, they are valued for their durability and resistance to corrosion, while manufacturers rely on them for precision components in automotive and aerospace applications. This cross-industry demand demonstrates their unmatched versatility.

1-800-221-5579

1-800-221-5579 info@lewisbrass.com

info@lewisbrass.com